by hupka | May 7, 2020 | Band Saw, Information

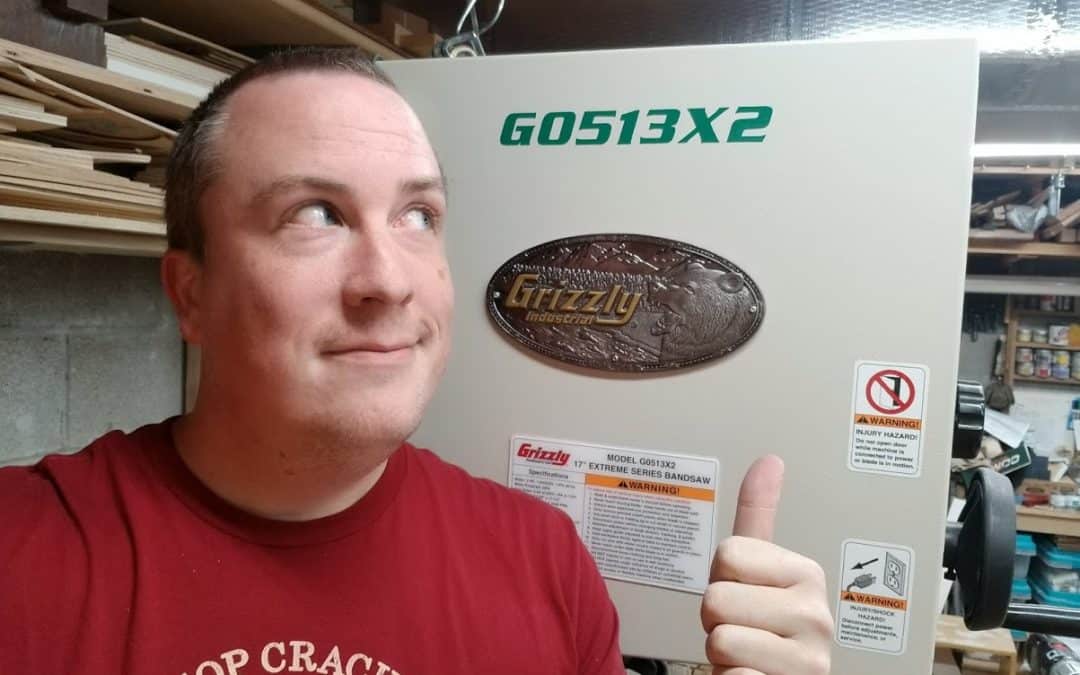

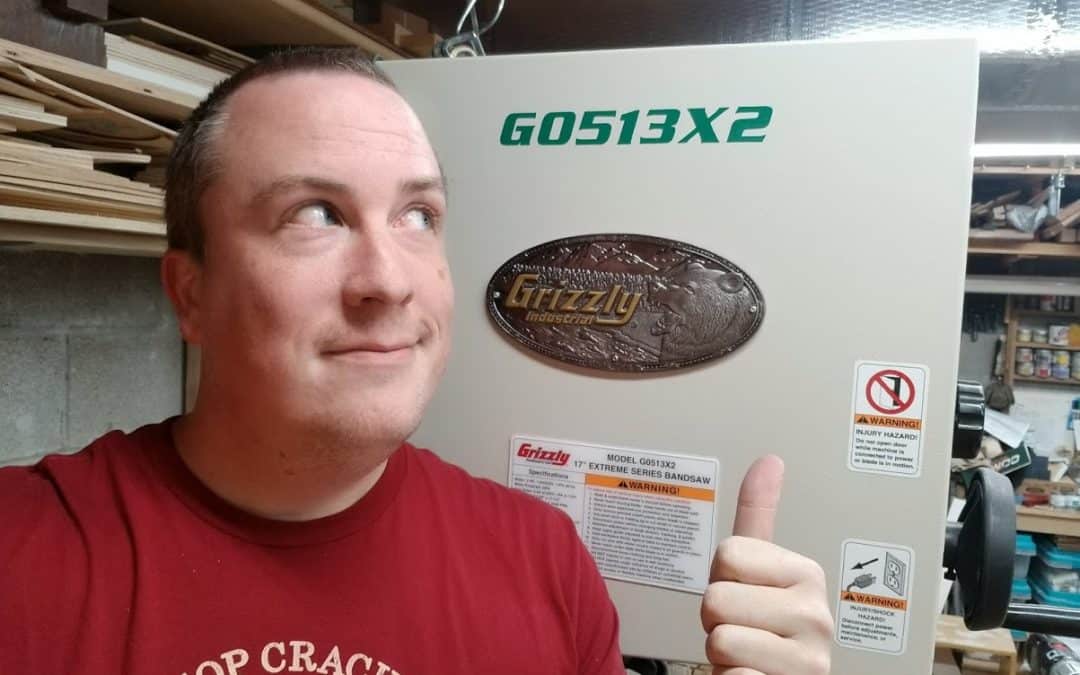

New tool day is always a great day in the woodshop. Back in November, we purchased the Grizzly 17″ G0513X2 bandsaw to replace our older 14″ Grizzly saw that had seen better days. We weren’t ready to bring it into the shop just yet because of the...

by hupka | Feb 20, 2019 | Band Saw, Woodshop

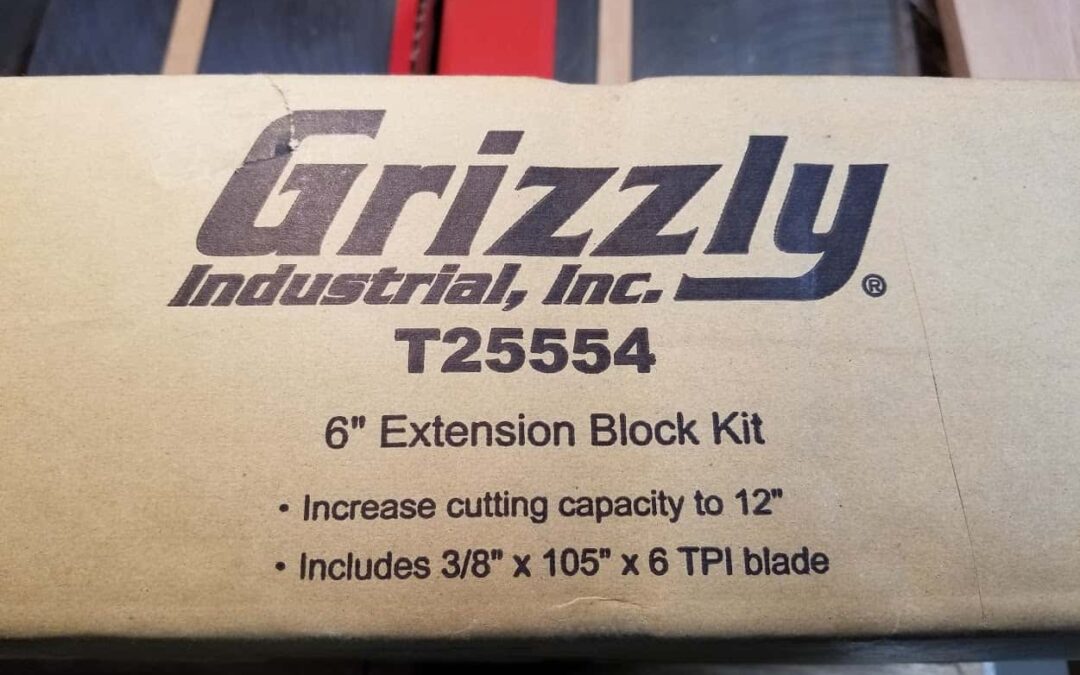

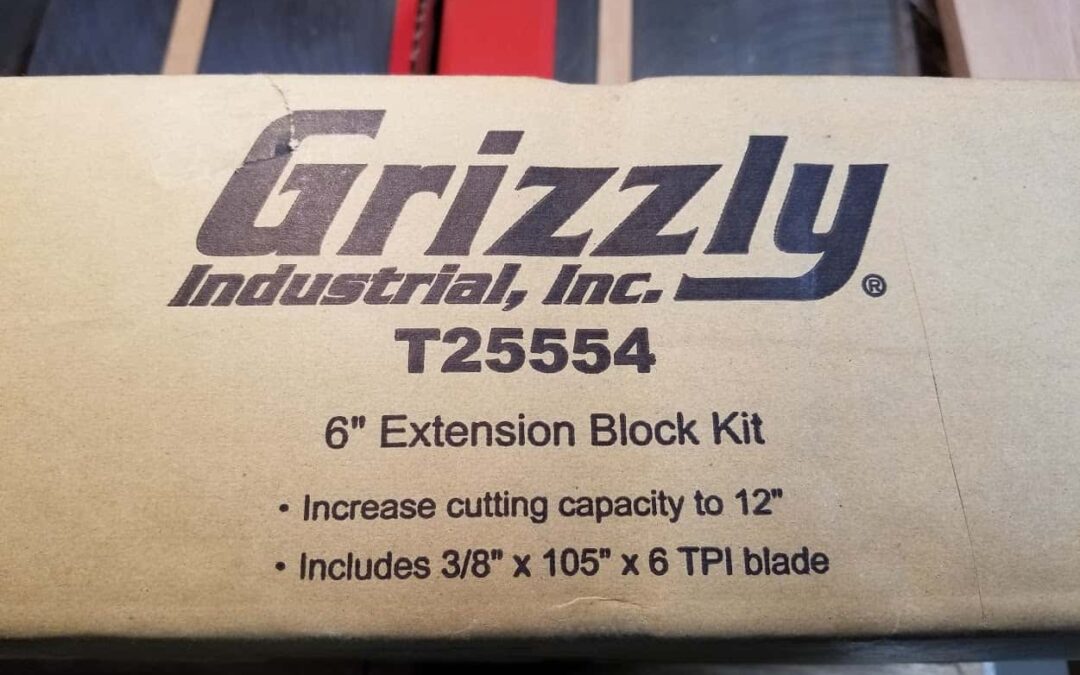

New toy day at the shop again. We currently run two Grizzly Industrial G0555 band saws at ES&S. Right out of the box they run a 93″ saw blade which is perfect for the majority of projects. One of our saws was upgraded with a 6″ riser kit several years...

by hupka | Jan 18, 2019 | Band Saw, Bits Blades, Dust Collector, Maintenance, Table Saw, Woodshop

Benson stopped by the shop to inspect our repair and rebuilding progress. He requires constant updates (and scratches) in his position as shop manager. So far we’ve upgraded the dust collection system, cleaned and greased the drum sander and craftsman table saw,...

by hupka | Jul 25, 2018 | Band Saw, Maintenance, Woodshop

Just because we buy high quality equipment doesn’t meant we get spared from the occasional breakdown. Our band saw suffered from having the lower alignment bearings lock up. This can happen for a number of reasons but most often from getting foreign material...

by hupka | Jun 30, 2018 | Band Saw, Care and Maintenance, Information

The bandsaw is one shop tool that finds its way into many homes. Not everyone will have a lathe or a planer but often the home hobbyist will have a bandsaw. Keeping that tool happy and useful is extremely important. We hear a lot of stories about people who are...

by hupka | Jan 19, 2018 | Band Saw, Information, Woodshop

There is no level of experience or skill that can overcome basic safety practices in the wood shop. This band saw blade broke on my while I was cutting through some soft pine. The drive wheel forced the blade to continue through the tension wheel and came rocketing...